By Echo | 02 January 2025 | 0 Comments

How to Terminate Fiber Optic Cable?

Terminating a fiber optic cable is a crucial process in establishing efficient, high-performance connections within communication networks. Proper termination ensures minimal signal loss and interference, contributing to optimal network functionality. Fiber optic cable termination can involve installing connectors or splicing fibers together. Here’s a comprehensive guide on the techniques, tools, and steps involved in this intricate procedure.

Fiber optic cable systems are intricate, requiring precision and adherence to high-quality standards. Rollball, a manufacturer specializing in high-performance fiber optic communication products and accessories, plays a pivotal role in providing components essential for successful cable terminations.

Safety First

Fiber optic cable termination involves working with delicate materials and glass fragments. Wearing safety glasses protects the eyes from potential hazards.

Remove the Outer Jacket

Using a stripping tool, carefully peel back the outer protective jacket. Take caution not to damage the underlying layers.

Eliminate Strength Members

Some fiber optic cables contain Kevlar or other strength materials. These must be removed to access the core.

Expose the Buffer Coating

Strip the buffer coating to the required length. This length depends on the connector type being installed.

Use a Fiber Cleaver

A fiber cleaver ensures precision, producing a clean cut at a perfect angle.

Inspect the Cleave

A microscope allows for a thorough inspection. The cleaved end should appear smooth, with no chips or cracks.

Select the Correct Connector

Choose a connector type, such as SC, LC, or ST, based on the application.

Prepare the Connector

Insert the stripped and cleaved fiber into the connector body, ensuring proper alignment.

Apply Adhesive (If Required)

Some connectors use adhesives. Follow the manufacturer’s instructions for applying and curing the adhesive.

Polish the Fiber End

Polishing eliminates imperfections at the fiber end, ensuring smooth connectivity. Angled polishing might be necessary depending on the connector type.

Microscopic Inspection

Examine the connector’s end face for scratches, chips, or debris.

Optical Tests

Conduct optical loss tests using tools like an Optical Time-Domain Reflectometer (OTDR) to measure insertion loss and return loss.

Connector Termination

Connectors offer convenience and flexibility, allowing for quick and repeatable connections.

Fusion Splicing

This method permanently joins two fibers by fusing them with heat. It offers low insertion loss but requires specialized equipment.

Mechanical Splicing

A simpler alternative to fusion splicing, this method uses alignment fixtures to join fibers. While faster, it may result in higher insertion loss.

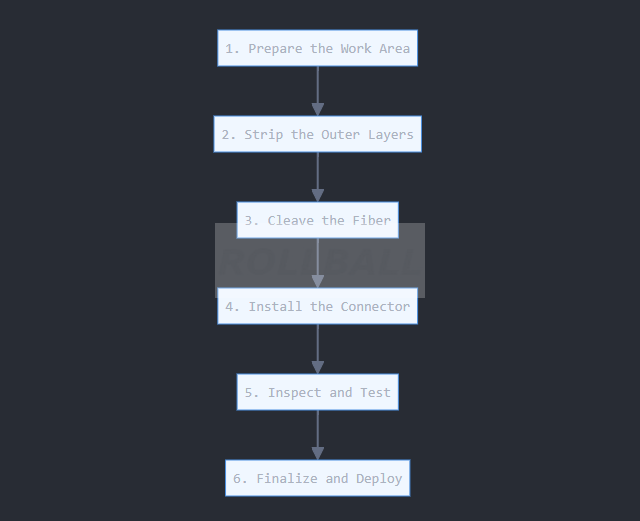

Diagram: Overview of Fiber Optic Termination Process

Below is a simplified representation of the fiber optic termination workflow.

Fiber optic cable systems are intricate, requiring precision and adherence to high-quality standards. Rollball, a manufacturer specializing in high-performance fiber optic communication products and accessories, plays a pivotal role in providing components essential for successful cable terminations.

Understanding Fiber Optic Cable Termination

Fiber optic termination refers to preparing the end of a fiber cable to connect it to a device, another cable, or a transceiver. It involves attaching connectors or splicing fibers together to create a seamless data transmission path. Successful termination minimizes signal degradation and ensures reliable connectivity.Preparation: Setting the Stage for Success

Before beginning the termination process, preparation is key. This includes gathering necessary tools and ensuring a safe working environment.Safety First

Fiber optic cable termination involves working with delicate materials and glass fragments. Wearing safety glasses protects the eyes from potential hazards.

Essential Tools and Materials

- Fiber optic cable

- Connectors (e.g., SC, LC, ST)

- Stripping tools

- Fiber optic cleaver

- Connector housing and inserts

- Adhesive (if applicable)

- Cleaning supplies (e.g., alcohol wipes, lint-free tissues)

- Microscope for inspection

Stripping the Fiber Optic Cable

Stripping the cable is the first critical step. This process involves removing protective layers to expose the fiber core.Remove the Outer Jacket

Using a stripping tool, carefully peel back the outer protective jacket. Take caution not to damage the underlying layers.

Eliminate Strength Members

Some fiber optic cables contain Kevlar or other strength materials. These must be removed to access the core.

Expose the Buffer Coating

Strip the buffer coating to the required length. This length depends on the connector type being installed.

Cleaving the Fiber: Precision Matters

Cleaving ensures a clean, perpendicular cut at the end of the fiber. This is essential for achieving high-quality terminations.Use a Fiber Cleaver

A fiber cleaver ensures precision, producing a clean cut at a perfect angle.

Inspect the Cleave

A microscope allows for a thorough inspection. The cleaved end should appear smooth, with no chips or cracks.

Installing the Connector

Connecting the fiber involves attaching it to the appropriate connector, a step that demands accuracy and precision.Select the Correct Connector

Choose a connector type, such as SC, LC, or ST, based on the application.

Prepare the Connector

Insert the stripped and cleaved fiber into the connector body, ensuring proper alignment.

Apply Adhesive (If Required)

Some connectors use adhesives. Follow the manufacturer’s instructions for applying and curing the adhesive.

Polish the Fiber End

Polishing eliminates imperfections at the fiber end, ensuring smooth connectivity. Angled polishing might be necessary depending on the connector type.

Inspection: Ensuring Quality

Inspecting the terminated cable is vital to ensure the connection meets performance standards.Microscopic Inspection

Examine the connector’s end face for scratches, chips, or debris.

Optical Tests

Conduct optical loss tests using tools like an Optical Time-Domain Reflectometer (OTDR) to measure insertion loss and return loss.

Termination Methods: Choosing the Right Approach

There are multiple methods for fiber optic cable termination, each with its own applications and advantages.Connector Termination

Connectors offer convenience and flexibility, allowing for quick and repeatable connections.

Fusion Splicing

This method permanently joins two fibers by fusing them with heat. It offers low insertion loss but requires specialized equipment.

Mechanical Splicing

A simpler alternative to fusion splicing, this method uses alignment fixtures to join fibers. While faster, it may result in higher insertion loss.

Key Considerations for Successful Termination

- Cleanliness: Maintaining a clean work environment prevents contamination, which can degrade performance.

- Precision Handling: Accurate alignment and handling are essential for reliable connections.

- Standards Compliance: Adhere to industry standards such as TIA/EIA and ISO for consistent results.

Rollball in Fiber Optic Termination

As a leader in fiber optic communication solutions, Rollball provides high-performance components essential for successful terminations. From durable fiber optic transceivers to precision-engineered connectors, Rollball’s products ensure reliable and efficient network installations.Diagram: Overview of Fiber Optic Termination Process

Below is a simplified representation of the fiber optic termination workflow.

Precision in Fiber Optic Termination

Terminating a fiber optic cable is a meticulous process that demands attention to detail and adherence to best practices. From stripping the cable to conducting rigorous inspections, each step contributes to creating a reliable, high-performance connection. By utilizing high-quality components such as those offered by Rollball, professionals can ensure the integrity and longevity of their fiber optic networks. With precision, preparation, and expertise, the termination process can seamlessly integrate with advanced communication infrastructures, supporting the demands of modern technology.Leave a Reply

Your email address will not be published.Required fields are marked. *